Our improvement journey began about two years ago. As we became more serious about the level of employee engagement with our improvement initiatives, we started soliciting improvement ideas from staff across our firm. Like many improvement professionals, we were expecting to receive “just do it” improvement ideas from staff that could be used as a vehicle for lean training and improvement culture development. Instead, the first ideas were over-arching problems that did not fit nicely into the model of the “just do it” or kaizen event that most continuous improvement cultures are built on.

It has been one year since we received those first ideas and we managed to attack both the large and small problems. We recently finished our first real “just do it” improvement and we’re excited to blog about it!

Our studio leader submitted the improvement idea after he observed someone scanning multiple documents into the network. He noticed that “to be scanned” documents were placed on a table five feet from the scanner and that there was not a good place to put the “scanned” drawings. The idea was submitted to the continuous improvement team, along with a proposed solution—rearrange the area around the scanner to create a more-efficient process.

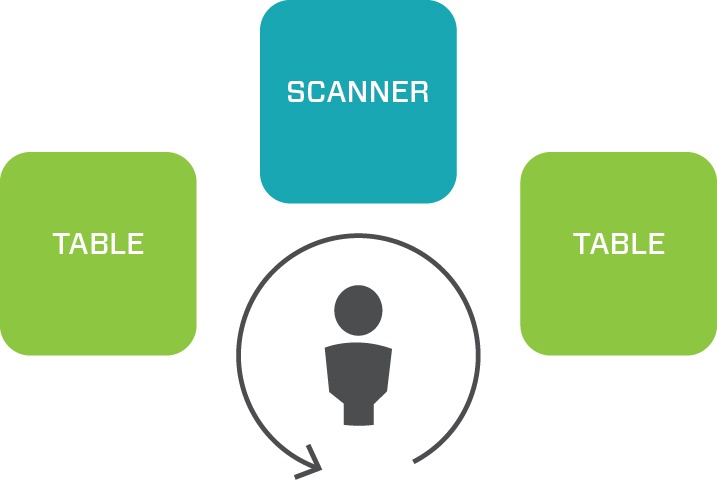

A cross-functional team met to discuss how the scanning process might be made easier. I used this as an opportunity to teach the team about work cells and explained how a work cell layout provides a compact space that supports a single piece moving through sequential stations. The team agreed that a work cell for the scanning process would make the task easier and more efficient.

Right away, we moved furniture around to accommodate the proposed solution. This included adding two new tables to the work area and cleaning up some items that did not belong in the space.

As we cleaned, we noticed the print room (where the scanner is located) could use a little 5S. This lean tool contains five tasks that begin with the letter “s” and its use results in a more organized and standardized work place, which allows for quicker detection and deeper root cause analysis when an object is found out of place. The five tasks are: sort, straighten, shine, standardize and sustain. We performed a quick 5S activity to reduce inventory and unused items, as well as put supplies closer to the place they are used. We are still working on the “sustain” portion of the 5S, however, as inventories have not been consistently reduced due to a recurring shipment.

One of our colleagues who uses the scanner regularly commented that the improved work cell saves her at least 30 seconds for each scan. One set of drawings could have at least 60 sheets, leading to an overall time savings of 30 minutes! That enables our colleague to spend 30 minutes doing another task that provides value to the firm.

Click the button below to see how Array’s culture of continuous improvement can help your organization.